Recent News

June 25, 2024

Key researchers from U.S. Department of Energy (DOE) national laboratories converged on NETL’s Albany, Oregon, site to discuss hydrogen energy-related research work of eXtremeMAT-H2— an NETL-led consortium of laboratories that accelerates the development of cost-effective alloys for use in the harsh environments of advanced energy systems.

Clean hydrogen is integral to achieving net-zero greenhouse gas emissions. Hydrogen offers significant potential to reduce carbon dioxide (CO2) in sectors that are difficult to decarbonize such as power generation, heavy duty transportation, chemicals production, and industrial heating. However, there are materials-related challenges.

At lower temperatures, exposure to hydrogen can make certain alloys brittle, which can lead to premature failure of components. However, little has been reported on the impact of hydrogen on the performance of alloys at elevated temperatures.

Alloys undergo a failure over time at elevated temperatures called “creep.” As a result, alloys begin to deform at loads below yield strength leading to component failure. Limited studies have shown that the creep life of alloys is decreased in hydrogen environments, even for alloys that show no hydrogen embrittlement under similar test conditions in short term tensile tests. With more and more power and industrial processes switching to hydrogen, it is important to understand the impact of hydrogen on the long-term performance of alloys at elevated temperatures.

NETL is currently evaluating the impacts of hydrogen on materials so that models can be developed that lead to an understanding of hydrogen-related impacts. The work will ultimately help establish a new domestic supply chain of hydrogen-resistant materials.

The eXtremeMAT approach harnesses the unique, world leading capabilities of national laboratories, in a focused, coordinated and collaborative way to demonstrate ways to design a new generation of computational and experimental validation toolsets accelerating the discovery, scale-up and manufacture of advanced energy materials for harsh service environments.

The original eXtremeMAT team consisted of NETL, Ames Lab, Idaho National Lab, Lawrence Livermore National Lab, Los Alamos National Lab, Oak Ridge National Lab, and Pacific Northwest National Lab. Specifically, the team developed a data-driven framework for predicting the creep behavior of steels used in construction of power plants.

The accomplishments of the consortium included development of models that can simulate 10 years of creep behavior in less than five hours; predictions for the impact of alloy chemistry including trace elements on creep performance; development of a framework for predicting creep performance of welds and the capability to model cyclical loading conditions.

The eXtremeMAT-H2 consortium is building on those successes and extending the tools developed for predicting long term alloy performance in hydrogen environments at elevated temperature service conditions. The eXtremeMAT-H2 team consist of researchers from NETL, Ames Lab, Los Alamos National Lab, Oak Ridge National Laboratory, and Sandia National Laboratories. Information on eXtremeMAT and eXtremeMAT-H2 can be found here.

According to NETL’s Associate Director of Materials Engineering and Manufacturing David Alman, “The new tools of eXtremeMAT-H2 team will allow for better predictive capability of alloy performance which can enhance the reliability and safety of components operating in hydrogen at elevated temperatures. This will aid in the transition to hydrogen to produce power, chemicals, steels and other applications.”

NETL is internationally recognized for its leadership in designing, developing, and deploying advanced materials for use in energy applications and extreme service environments. NETL researchers have designed, engineered, and evaluated materials ranging from atomistic to pilot-plant scales and it uses a one-of-a-kind suite of computational and experimental methods for translating new material science concepts into practical technologies.

Construction of the Advanced Alloy Signature Center, a complete alloy development facility capable of prototyping alloys at scales that advance commercialization is underway at the Albany site. The center represents a significant investment to accelerate commercialization of superalloys and other high-performance materials needed to develop corrosion-resistant components for environmentally friendly, highly efficient hydrogen energy facilities, power plants, advanced manufacturing processes in growing industries and applications vital to national security.

During their visit to Albany, consortium representatives toured NETL’s Melt Processing Laboratory, Thermo-Mechanical Processing Lab, Environmental Mechanical Testing Lab, Thermo-Physical Testing Lab, High Pressure Immersion and Reactive Transport lab, Geoscience, Artificial Intelligence, and Analysis Lab.

NETL is a DOE national laboratory that drives innovation and delivers solutions for an environmentally sustainable and prosperous energy future. By using its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.

Source

Key researchers from U.S. Department of Energy (DOE) national laboratories converged on NETL’s Albany, Oregon, site to discuss hydrogen energy-related research work of eXtremeMAT-H2— an NETL-led consortium of laboratories that accelerates the development of cost-effective alloys for use in the harsh environments of advanced energy systems.

Clean hydrogen is integral to achieving net-zero greenhouse gas emissions. Hydrogen offers significant potential to reduce carbon dioxide (CO2) in sectors that are difficult to decarbonize such as power generation, heavy duty transportation, chemicals production, and industrial heating. However, there are materials-related challenges.

At lower temperatures, exposure to hydrogen can make certain alloys brittle, which can lead to premature failure of components. However, little has been reported on the impact of hydrogen on the performance of alloys at elevated temperatures.

Alloys undergo a failure over time at elevated temperatures called “creep.” As a result, alloys begin to deform at loads below yield strength leading to component failure. Limited studies have shown that the creep life of alloys is decreased in hydrogen environments, even for alloys that show no hydrogen embrittlement under similar test conditions in short term tensile tests. With more and more power and industrial processes switching to hydrogen, it is important to understand the impact of hydrogen on the long-term performance of alloys at elevated temperatures.

NETL is currently evaluating the impacts of hydrogen on materials so that models can be developed that lead to an understanding of hydrogen-related impacts. The work will ultimately help establish a new domestic supply chain of hydrogen-resistant materials.

The eXtremeMAT approach harnesses the unique, world leading capabilities of national laboratories, in a focused, coordinated and collaborative way to demonstrate ways to design a new generation of computational and experimental validation toolsets accelerating the discovery, scale-up and manufacture of advanced energy materials for harsh service environments.

The original eXtremeMAT team consisted of NETL, Ames Lab, Idaho National Lab, Lawrence Livermore National Lab, Los Alamos National Lab, Oak Ridge National Lab, and Pacific Northwest National Lab. Specifically, the team developed a data-driven framework for predicting the creep behavior of steels used in construction of power plants.

The accomplishments of the consortium included development of models that can simulate 10 years of creep behavior in less than five hours; predictions for the impact of alloy chemistry including trace elements on creep performance; development of a framework for predicting creep performance of welds and the capability to model cyclical loading conditions.

The eXtremeMAT-H2 consortium is building on those successes and extending the tools developed for predicting long term alloy performance in hydrogen environments at elevated temperature service conditions. The eXtremeMAT-H2 team consist of researchers from NETL, Ames Lab, Los Alamos National Lab, Oak Ridge National Laboratory, and Sandia National Laboratories. Information on eXtremeMAT and eXtremeMAT-H2 can be found here.

According to NETL’s Associate Director of Materials Engineering and Manufacturing David Alman, “The new tools of eXtremeMAT-H2 team will allow for better predictive capability of alloy performance which can enhance the reliability and safety of components operating in hydrogen at elevated temperatures. This will aid in the transition to hydrogen to produce power, chemicals, steels and other applications.”

NETL is internationally recognized for its leadership in designing, developing, and deploying advanced materials for use in energy applications and extreme service environments. NETL researchers have designed, engineered, and evaluated materials ranging from atomistic to pilot-plant scales and it uses a one-of-a-kind suite of computational and experimental methods for translating new material science concepts into practical technologies.

Construction of the Advanced Alloy Signature Center, a complete alloy development facility capable of prototyping alloys at scales that advance commercialization is underway at the Albany site. The center represents a significant investment to accelerate commercialization of superalloys and other high-performance materials needed to develop corrosion-resistant components for environmentally friendly, highly efficient hydrogen energy facilities, power plants, advanced manufacturing processes in growing industries and applications vital to national security.

During their visit to Albany, consortium representatives toured NETL’s Melt Processing Laboratory, Thermo-Mechanical Processing Lab, Environmental Mechanical Testing Lab, Thermo-Physical Testing Lab, High Pressure Immersion and Reactive Transport lab, Geoscience, Artificial Intelligence, and Analysis Lab.

NETL is a DOE national laboratory that drives innovation and delivers solutions for an environmentally sustainable and prosperous energy future. By using its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.

Source

May 13, 2024

The brightest minds in the Oregon federal workforce gathered Tuesday, May 7, at the Historic Hangar, located adjacent to Pearson Air Museum, in Vancouver, Washington, for the Oregon Federal Executive Board (FEB) Excellence in Government Awards, where an NETL researcher took home a prestigious honor

NETL’s Jennifer Bauer received the award for Outstanding Innovator from the Oregon FEB for her work leading NETL’s Geoscience, Artificial Intelligence, and Analysis (GAIA) team, which integrated thousands of disparate public data resources to support clean energy and energy community activities within the Lab, the U.S. Department of Energy (DOE) and other federal agencies.

The Biden Administration has prioritized a clean energy transition that does not leave energy communities behind. However, most of the data on these communities did not exist in a single comprehensive resource. Additionally, the information available was often organized in a way that would require significant processing to unlock the data.

Bauer and her team have worked to integrate data resources that provide insights into existing energy facilities and infrastructure assets, energy resource potential, ongoing energy activities and projects, workforce and jobs, environmental conditions and community demographics to label and compile massive volumes of data for advanced, multi-scale analysis.

With these new foundational data resources, Bauer has rapidly developed custom mapping applications that have helped stakeholders and policymakers identify opportunities for economic improvement and environmental justice in communities that will be impacted by the changing energy landscape. The release and sharing of these datasets and maps provided important information for these communities, allowing them to evaluate funding and tax credit options and opportunities to support clean energy transitions.

Among other successes, these efforts resulted in the creation of several publicly accessible maps and data resources for the NETL-supported Interagency Working Group (IWG) on Coal and Power Plant Communities and Economic Revitalization. The team also produced the Coal Power Plant Redevelopment Visualization Tool, which helps identify opportunities for the redevelopment of shuttered coal-fired power plants to support community reinvestment.

The GAIA team also worked with DOE to review authoritative, nationwide datasets and define eligibility criteria for the Communities LEAP (Local Energy Action Program) Pilot, which was launched to facilitate sustained community-wide economic and environmental benefits. The goal is to empower low-income and energy-burdened communities with historic reliance on fossil industries or communities experiencing environmental injustice to design community-based pathways to a sustainable, resilient, equitable clean energy future. Bauer’s data helped inform the selection of 24 communities for the pilot.

These successes have led to multiple other impacts that support energy transition opportunities for different stakeholder groups across the nation. Her work with the GAIA team is accelerating responsible community transitions for energy communities by providing them with data-driven tools to identify opportunities for economic growth in their domains. This approach will create new jobs, improve public health, and provide a range of community benefits — all driven by the foundation of data that Bauer has worked diligently to build and make accessible across the United States.

The Oregon FEB Excellence in Government Awards recognize outstanding federal employees for efforts that encourage innovation and excellence in government, reinforce pride in federal service and call public attention to the broad range of services provided by federal employees. The winners of the FEB Excellence in Government Awards are selected by an independent committee of federal executives.

Source

The brightest minds in the Oregon federal workforce gathered Tuesday, May 7, at the Historic Hangar, located adjacent to Pearson Air Museum, in Vancouver, Washington, for the Oregon Federal Executive Board (FEB) Excellence in Government Awards, where an NETL researcher took home a prestigious honor

NETL’s Jennifer Bauer received the award for Outstanding Innovator from the Oregon FEB for her work leading NETL’s Geoscience, Artificial Intelligence, and Analysis (GAIA) team, which integrated thousands of disparate public data resources to support clean energy and energy community activities within the Lab, the U.S. Department of Energy (DOE) and other federal agencies.

The Biden Administration has prioritized a clean energy transition that does not leave energy communities behind. However, most of the data on these communities did not exist in a single comprehensive resource. Additionally, the information available was often organized in a way that would require significant processing to unlock the data.

Bauer and her team have worked to integrate data resources that provide insights into existing energy facilities and infrastructure assets, energy resource potential, ongoing energy activities and projects, workforce and jobs, environmental conditions and community demographics to label and compile massive volumes of data for advanced, multi-scale analysis.

With these new foundational data resources, Bauer has rapidly developed custom mapping applications that have helped stakeholders and policymakers identify opportunities for economic improvement and environmental justice in communities that will be impacted by the changing energy landscape. The release and sharing of these datasets and maps provided important information for these communities, allowing them to evaluate funding and tax credit options and opportunities to support clean energy transitions.

Among other successes, these efforts resulted in the creation of several publicly accessible maps and data resources for the NETL-supported Interagency Working Group (IWG) on Coal and Power Plant Communities and Economic Revitalization. The team also produced the Coal Power Plant Redevelopment Visualization Tool, which helps identify opportunities for the redevelopment of shuttered coal-fired power plants to support community reinvestment.

The GAIA team also worked with DOE to review authoritative, nationwide datasets and define eligibility criteria for the Communities LEAP (Local Energy Action Program) Pilot, which was launched to facilitate sustained community-wide economic and environmental benefits. The goal is to empower low-income and energy-burdened communities with historic reliance on fossil industries or communities experiencing environmental injustice to design community-based pathways to a sustainable, resilient, equitable clean energy future. Bauer’s data helped inform the selection of 24 communities for the pilot.

These successes have led to multiple other impacts that support energy transition opportunities for different stakeholder groups across the nation. Her work with the GAIA team is accelerating responsible community transitions for energy communities by providing them with data-driven tools to identify opportunities for economic growth in their domains. This approach will create new jobs, improve public health, and provide a range of community benefits — all driven by the foundation of data that Bauer has worked diligently to build and make accessible across the United States.

The Oregon FEB Excellence in Government Awards recognize outstanding federal employees for efforts that encourage innovation and excellence in government, reinforce pride in federal service and call public attention to the broad range of services provided by federal employees. The winners of the FEB Excellence in Government Awards are selected by an independent committee of federal executives.

Source

May 2, 2024

NETL publicly released an award-winning analytical tool that uses advanced big data computing, artificial intelligence (AI), machine learning (ML) and advanced analytical models to evaluate energy infrastructure integrity — a capability that can lead to effective cost savings and improved operational measures for environmental safety.

The NETL-developed Advanced Infrastructure Integrity Model (AIIM) web mapping application is available on the Department of Energy’s Energy Data eXchange® (EDX). Recognized with a 2022 Tech Connect National Innovation Award, AIIM has been acknowledged as a standout technology in its field.

AIIM can be applied to evaluate the integrity of offshore energy infrastructure, including pipelines and platforms. Infrastructure, like those in the Gulf of

Mexico, play an essential role in ensuring access to safe and secure energy for the United States. According to the U.S. Energy Information Administration, production in the Gulf of Mexico accounts for 15% of total crude and 5% of total natural gas from the United States.

AIIM began in 2018 as an approach to assess offshore energy infrastructure integrity but has also been used to perform onshore infrastructure assessments related to carbon capture, transport and storage research, and more.

Jennifer Bauer, a geo-data scientist at NETL, explained that, because of growing national efforts to decarbonize, existing infrastructure may also be reused for other energy purposes.

“Many of these structures have been operating past their original design life, while others are at risk of attrition before return on investment,” she said. “To better understand the potential for reuse or life extension opportunities, an assessment of the infrastructure integrity is critical to inform decision making. AIIM provides key insights for assessing structural integrity related to infrastructure use and reuse. It’s a better way to develop risk prevention planning for regulators, researchers and industry.”

Kelly Rose, Ph.D., senior fellow of computational science and engineering at NETL, added that AIIM builds upon the Department of Energy’s supercomputing, AI and geo-data capabilities.

“AIIM integrates big data, big data computing, and multiple ML and advanced analytical models to evaluate energy infrastructure integrity,” she said. “This tool was developed in support of NETL’s Science-based AI/ML Institute (SAMI), which uses AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production.”

AIIM applies a series of machine learning models to multiple public datasets representing components of the natural-engineered system and forecasts potential risk and remaining lifespan of infrastructure. AIIM integrates factors representing stressors, like daily operational wear-and-tear, environmental and geologic variables, reported incidents, and structural characteristics. The comprehensive evaluation helps quantify remaining life spans and identify potential integrity issues before they occur.

“To better understand the potential for life extension opportunities as well as remediation needs, AIIM provides key scientific and data-driven insights that can help secure our energy infrastructure, support risk prevention, inform maintenance and regulatory inspection plans and ultimately provide cost savings and measures that ensure operational and environmental safety,” Bauer said. “AIIM is paving the way for safe, sustainable and scientifically supervised AI-informed carbon-neutral solutions through infrastructure integrity technology.”

Source

NETL publicly released an award-winning analytical tool that uses advanced big data computing, artificial intelligence (AI), machine learning (ML) and advanced analytical models to evaluate energy infrastructure integrity — a capability that can lead to effective cost savings and improved operational measures for environmental safety.

The NETL-developed Advanced Infrastructure Integrity Model (AIIM) web mapping application is available on the Department of Energy’s Energy Data eXchange® (EDX). Recognized with a 2022 Tech Connect National Innovation Award, AIIM has been acknowledged as a standout technology in its field.

AIIM can be applied to evaluate the integrity of offshore energy infrastructure, including pipelines and platforms. Infrastructure, like those in the Gulf of

Mexico, play an essential role in ensuring access to safe and secure energy for the United States. According to the U.S. Energy Information Administration, production in the Gulf of Mexico accounts for 15% of total crude and 5% of total natural gas from the United States.

AIIM began in 2018 as an approach to assess offshore energy infrastructure integrity but has also been used to perform onshore infrastructure assessments related to carbon capture, transport and storage research, and more.

Jennifer Bauer, a geo-data scientist at NETL, explained that, because of growing national efforts to decarbonize, existing infrastructure may also be reused for other energy purposes.

“Many of these structures have been operating past their original design life, while others are at risk of attrition before return on investment,” she said. “To better understand the potential for reuse or life extension opportunities, an assessment of the infrastructure integrity is critical to inform decision making. AIIM provides key insights for assessing structural integrity related to infrastructure use and reuse. It’s a better way to develop risk prevention planning for regulators, researchers and industry.”

Kelly Rose, Ph.D., senior fellow of computational science and engineering at NETL, added that AIIM builds upon the Department of Energy’s supercomputing, AI and geo-data capabilities.

“AIIM integrates big data, big data computing, and multiple ML and advanced analytical models to evaluate energy infrastructure integrity,” she said. “This tool was developed in support of NETL’s Science-based AI/ML Institute (SAMI), which uses AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production.”

AIIM applies a series of machine learning models to multiple public datasets representing components of the natural-engineered system and forecasts potential risk and remaining lifespan of infrastructure. AIIM integrates factors representing stressors, like daily operational wear-and-tear, environmental and geologic variables, reported incidents, and structural characteristics. The comprehensive evaluation helps quantify remaining life spans and identify potential integrity issues before they occur.

“To better understand the potential for life extension opportunities as well as remediation needs, AIIM provides key scientific and data-driven insights that can help secure our energy infrastructure, support risk prevention, inform maintenance and regulatory inspection plans and ultimately provide cost savings and measures that ensure operational and environmental safety,” Bauer said. “AIIM is paving the way for safe, sustainable and scientifically supervised AI-informed carbon-neutral solutions through infrastructure integrity technology.”

Source

April 4, 2024

The continual growth of geologic carbon storage projects calls for the growth of comprehensive data resources to support project planning, geologic characterization and risk analysis. Researchers at NETL recently published a new dataset, the Catalog of U.S. Prospective Subsurface Storage Reservoir Sealing Formations, that aggregates prospective seal units for potential storage resources within the U.S. for geologic carbon storage in both onshore and offshore basins.

“The catalog aims to guide users to available literature and data resources related to containment systems for carbon dioxide (CO2) storage, a vital component in the mission to achieve a net-zero carbon emissions energy sector and economy by 2050,” said NETL Geologist Paige Morkner. “This is the first version of this catalog and is a valuable resource for researchers, policymakers and industry professionals interested in geologic carbon storage and the identification of prospective seal units in U.S. sedimentary basins.”

The catalog lists prospective seals by unit name along with associated data and resources that are available, including lithology, position with respect to the reservoir (primary, secondary, intraformational, etc.) and age (geologic period), for prospective domestic geologic storage resources.

The information source for each record in the catalog also includes the published citation, year of publication, resource type (journal article, event proceedings, etc.) and additional record notes. The catalog is the result of a significant effort to aggregate disparate data resources into a single dataset that guides users to understand what prospective seal units exist in deep sedimentary basins.

Access the dataset on NETL's Energy Data eXchange® (EDX) and EDX® disCO2ver, NETL's carbon storage-centric virtual data collaboration and curation platform, to explore this important resource further.

EDX is the U.S. Department of Energy (DOE) Office of Fossil Energy and Carbon Management’s (FECM) virtual library and data laboratory built to find, connect, curate, use and re-use data to advance fossil energy and environmental research and development. Developed and maintained by NETL, EDX supports the entire life cycle of data by offering secure, private collaborative workspaces for ongoing research projects until they mature and become catalogued, curated and published. EDX adheres to DOE cyber policies and domestic and international standards for data curation and citation. This ensures data products pushed public via EDX are afforded a citation for proper accreditation and comply with journal publication requirements.

Source

The continual growth of geologic carbon storage projects calls for the growth of comprehensive data resources to support project planning, geologic characterization and risk analysis. Researchers at NETL recently published a new dataset, the Catalog of U.S. Prospective Subsurface Storage Reservoir Sealing Formations, that aggregates prospective seal units for potential storage resources within the U.S. for geologic carbon storage in both onshore and offshore basins.

“The catalog aims to guide users to available literature and data resources related to containment systems for carbon dioxide (CO2) storage, a vital component in the mission to achieve a net-zero carbon emissions energy sector and economy by 2050,” said NETL Geologist Paige Morkner. “This is the first version of this catalog and is a valuable resource for researchers, policymakers and industry professionals interested in geologic carbon storage and the identification of prospective seal units in U.S. sedimentary basins.”

The catalog lists prospective seals by unit name along with associated data and resources that are available, including lithology, position with respect to the reservoir (primary, secondary, intraformational, etc.) and age (geologic period), for prospective domestic geologic storage resources.

The information source for each record in the catalog also includes the published citation, year of publication, resource type (journal article, event proceedings, etc.) and additional record notes. The catalog is the result of a significant effort to aggregate disparate data resources into a single dataset that guides users to understand what prospective seal units exist in deep sedimentary basins.

Access the dataset on NETL's Energy Data eXchange® (EDX) and EDX® disCO2ver, NETL's carbon storage-centric virtual data collaboration and curation platform, to explore this important resource further.

EDX is the U.S. Department of Energy (DOE) Office of Fossil Energy and Carbon Management’s (FECM) virtual library and data laboratory built to find, connect, curate, use and re-use data to advance fossil energy and environmental research and development. Developed and maintained by NETL, EDX supports the entire life cycle of data by offering secure, private collaborative workspaces for ongoing research projects until they mature and become catalogued, curated and published. EDX adheres to DOE cyber policies and domestic and international standards for data curation and citation. This ensures data products pushed public via EDX are afforded a citation for proper accreditation and comply with journal publication requirements.

Source

May 13, 2024

The brightest minds in the Oregon federal workforce gathered Tuesday, May 7, at the Historic Hangar, located adjacent to Pearson Air Museum, in Vancouver, Washington, for the Oregon Federal Executive Board (FEB) Excellence in Government Awards, where an NETL researcher took home a prestigious honor.

NETL’s Jennifer Bauer received the award for Outstanding Innovator from the Oregon FEB for her work leading NETL’s Geoscience, Artificial Intelligence, and Analysis (GAIA) team, which integrated thousands of disparate public data resources to support clean energy and energy community activities within the Lab, the U.S. Department of Energy (DOE) and other federal agencies.

The Biden Administration has prioritized a clean energy transition that does not leave energy communities behind. However, most of the data on these communities did not exist in a single comprehensive resource. Additionally, the information available was often organized in a way that would require significant processing to unlock the data.

Bauer and her team have worked to integrate data resources that provide insights into existing energy facilities and infrastructure assets, energy resource potential, ongoing energy activities and projects, workforce and jobs, environmental conditions and community demographics to label and compile massive volumes of data for advanced, multi-scale analysis.

With these new foundational data resources, Bauer has rapidly developed custom mapping applications that have helped stakeholders and policymakers identify opportunities for economic improvement and environmental justice in communities that will be impacted by the changing energy landscape. The release and sharing of these datasets and maps provided important information for these communities, allowing them to evaluate funding and tax credit options and opportunities to support clean energy transitions.

Among other successes, these efforts resulted in the creation of several publicly accessible maps and data resources for the NETL-supported Interagency Working Group (IWG) on Coal and Power Plant Communities and Economic Revitalization. The team also produced the Coal Power Plant Redevelopment Visualization Tool, which helps identify opportunities for the redevelopment of shuttered coal-fired power plants to support community reinvestment.

The GAIA team also worked with DOE to review authoritative, nationwide datasets and define eligibility criteria for the Communities LEAP (Local Energy Action Program) Pilot, which was launched to facilitate sustained community-wide economic and environmental benefits. The goal is to empower low-income and energy-burdened communities with historic reliance on fossil industries or communities experiencing environmental injustice to design community-based pathways to a sustainable, resilient, equitable clean energy future. Bauer’s data helped inform the selection of 24 communities for the pilot.

These successes have led to multiple other impacts that support energy transition opportunities for different stakeholder groups across the nation. Her work with the GAIA team is accelerating responsible community transitions for energy communities by providing them with data-driven tools to identify opportunities for economic growth in their domains. This approach will create new jobs, improve public health, and provide a range of community benefits — all driven by the foundation of data that Bauer has worked diligently to build and make accessible across the United States.

The Oregon FEB Excellence in Government Awards recognize outstanding federal employees for efforts that encourage innovation and excellence in government, reinforce pride in federal service and call public attention to the broad range of services provided by federal employees. The winners of the FEB Excellence in Government Awards are selected by an independent committee of federal executives.

Source

May 2, 2024

NETL publicly released an award-winning analytical tool that uses advanced big data computing, artificial intelligence (AI), machine learning (ML) and advanced analytical models to evaluate energy infrastructure integrity — a capability that can lead to effective cost savings and improved operational measures for environmental safety.

The NETL-developed Advanced Infrastructure Integrity Model (AIIM) web mapping application is available on the Department of Energy’s Energy Data eXchange® (EDX). Recognized with a 2022 Tech Connect National Innovation Award, AIIM has been acknowledged as a standout technology in its field.

AIIM can be applied to evaluate the integrity of offshore energy infrastructure, including pipelines and platforms. Infrastructure, like those in the Gulf of Mexico, play an essential role in ensuring access to safe and secure energy for the United States. According to the U.S. Energy Information Administration, production in the Gulf of Mexico accounts for 15% of total crude and 5% of total natural gas from the United States.

AIIM began in 2018 as an approach to assess offshore energy infrastructure integrity but has also been used to perform onshore infrastructure assessments related to carbon capture, transport and storage research, and more.

Jennifer Bauer, a geo-data scientist at NETL, explained that, because of growing national efforts to decarbonize, existing infrastructure may also be reused

for other energy purposes.

“Many of these structures have been operating past their original design life, while others are at risk of attrition before return on investment,” she said. “To better understand the potential for reuse or life extension opportunities, an assessment of the infrastructure integrity is critical to inform decision making. AIIM provides key insights for assessing structural integrity related to infrastructure use and reuse. It’s a better way to develop risk prevention planning for regulators, researchers and industry.”

Kelly Rose, Ph.D., senior fellow of computational science and engineering at NETL, added that AIIM builds upon the Department of Energy’s

supercomputing, AI and geo-data capabilities.

“AIIM integrates big data, big data computing, and multiple ML and advanced analytical models to evaluate energy infrastructure integrity,” she said. “This tool was developed in support of NETL’s Science-based AI/ML Institute (SAMI), which uses AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production.”

AIIM applies a series of machine learning models to multiple public datasets representing components of the natural-engineered system and forecasts potential risk and remaining lifespan of infrastructure. AIIM integrates factors representing stressors, like daily operational wear-and-tear, environmental and geologic variables, reported incidents, and structural characteristics. The comprehensive evaluation helps quantify remaining life spans and identify potential integrity issues before they occur.

“To better understand the potential for life extension opportunities as well as remediation needs, AIIM provides key scientific and data-driven insights that can help secure our energy infrastructure, support risk prevention, inform maintenance and regulatory inspection plans and ultimately provide cost savings and measures that ensure operational and environmental safety,” Bauer said. “AIIM is paving the way for safe, sustainable and scientifically supervised AI-informed carbon-neutral solutions through infrastructure integrity technology.”

Source

NETL publicly released an award-winning analytical tool that uses advanced big data computing, artificial intelligence (AI), machine learning (ML) and advanced analytical models to evaluate energy infrastructure integrity — a capability that can lead to effective cost savings and improved operational measures for environmental safety.

The NETL-developed Advanced Infrastructure Integrity Model (AIIM) web mapping application is available on the Department of Energy’s Energy Data eXchange® (EDX). Recognized with a 2022 Tech Connect National Innovation Award, AIIM has been acknowledged as a standout technology in its field.

AIIM can be applied to evaluate the integrity of offshore energy infrastructure, including pipelines and platforms. Infrastructure, like those in the Gulf of Mexico, play an essential role in ensuring access to safe and secure energy for the United States. According to the U.S. Energy Information Administration, production in the Gulf of Mexico accounts for 15% of total crude and 5% of total natural gas from the United States.

AIIM began in 2018 as an approach to assess offshore energy infrastructure integrity but has also been used to perform onshore infrastructure assessments related to carbon capture, transport and storage research, and more.

Jennifer Bauer, a geo-data scientist at NETL, explained that, because of growing national efforts to decarbonize, existing infrastructure may also be reused

for other energy purposes.

“Many of these structures have been operating past their original design life, while others are at risk of attrition before return on investment,” she said. “To better understand the potential for reuse or life extension opportunities, an assessment of the infrastructure integrity is critical to inform decision making. AIIM provides key insights for assessing structural integrity related to infrastructure use and reuse. It’s a better way to develop risk prevention planning for regulators, researchers and industry.”

Kelly Rose, Ph.D., senior fellow of computational science and engineering at NETL, added that AIIM builds upon the Department of Energy’s

supercomputing, AI and geo-data capabilities.

“AIIM integrates big data, big data computing, and multiple ML and advanced analytical models to evaluate energy infrastructure integrity,” she said. “This tool was developed in support of NETL’s Science-based AI/ML Institute (SAMI), which uses AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production.”

AIIM applies a series of machine learning models to multiple public datasets representing components of the natural-engineered system and forecasts potential risk and remaining lifespan of infrastructure. AIIM integrates factors representing stressors, like daily operational wear-and-tear, environmental and geologic variables, reported incidents, and structural characteristics. The comprehensive evaluation helps quantify remaining life spans and identify potential integrity issues before they occur.

“To better understand the potential for life extension opportunities as well as remediation needs, AIIM provides key scientific and data-driven insights that can help secure our energy infrastructure, support risk prevention, inform maintenance and regulatory inspection plans and ultimately provide cost savings and measures that ensure operational and environmental safety,” Bauer said. “AIIM is paving the way for safe, sustainable and scientifically supervised AI-informed carbon-neutral solutions through infrastructure integrity technology.”

Source

March 8, 2024

Zineb Belarbi, Ph.D., a leading corrosion and electrochemistry researcher at NETL’s Albany, Oregon, facility, was recognized by the Association for Materials Protection and Performance (AMPP) with the Joyce Wright Industry Impact Award in ceremonies held at the association’s annual conference March 6 in New Orleans.

The Joyce Wright Industry Impact Award recognizes women who have contributed to creating a positive impact on the culture of the materials protection and performance industry, mentoring, and providing wisdom to others in the industry. It is named for Joyce Wright, chair of AMPP Global Center and process improvement specialist at Huntington Ingals Industries Newport News Shipbuilding.

Belarbi’s work focuses on overcoming corrosion challenges in the nation’s methane mitigation and CO2 transport and storage efforts. She is a regular contributor to AMPP conferences and publications.

“My research at NETL focuses on evaluation of corrosion performance of steel alloys and mitigation of internal corrosion in natural gas pipelines,” Belarbi explained last year. “In addition, I support other projects such as the National Energy Water Treatment and Speciation (NEWTS) Database and geologic carbon storage.”

Belarbi was part of an NETL team that invented a new self-healing cold spray coating for internal pipeline corrosion protection that can help protect against corrosion in natural gas, hydrogen and CO2 pipelines. Pipeline corrosion can cause catastrophic failure events such as explosions and emissions of environmentally damaging substances like methane.

“My professor at college inspired me to pursue a career of engineering,” Belarbi said. “I am a very curious and experimental person, and I love that the combination of engineering and chemistry offers us the ability to design and create new materials that can improve and advance the economy.”

Belarbi received a Ph.D. in chemical engineering from Sorbonne University (ex. Pierre and Marie Curie University-Paris IV) France in 2013. She built a solid background in electrochemistry to further explore the inhibition of calcium carbonate deposition on metal surfaces.

Before joining NETL, Belarbi was a project leader at the Institute for Corrosion and Multiphase Technology at Ohio University where her research focused on using corrosion inhibitors to mitigate internal corrosion in oil and gas pipelines. Belarbi also worked at the Institute for Sustainable Energy and the Environment, Ohio University, where she investigated the electrochemical removal of nutrients from animal wastewater.

AMPP is a global community of professionals focused on the protection of assets and the performance of industrial and natural materials. AMPP is the world’s largest corrosion control and protective coatings organization, serving more than 35,000 members in over 140 countries. AMPP is headquartered in the United States with offices in Houston and Pittsburgh, and additional offices in Brazil, Canada, China, Dubai (training center), Malaysia, Saudi Arabia and the United Kingdom.

Source

Zineb Belarbi, Ph.D., a leading corrosion and electrochemistry researcher at NETL’s Albany, Oregon, facility, was recognized by the Association for Materials Protection and Performance (AMPP) with the Joyce Wright Industry Impact Award in ceremonies held at the association’s annual conference March 6 in New Orleans.

The Joyce Wright Industry Impact Award recognizes women who have contributed to creating a positive impact on the culture of the materials protection and performance industry, mentoring, and providing wisdom to others in the industry. It is named for Joyce Wright, chair of AMPP Global Center and process improvement specialist at Huntington Ingals Industries Newport News Shipbuilding.

Belarbi’s work focuses on overcoming corrosion challenges in the nation’s methane mitigation and CO2 transport and storage efforts. She is a regular contributor to AMPP conferences and publications.

“My research at NETL focuses on evaluation of corrosion performance of steel alloys and mitigation of internal corrosion in natural gas pipelines,” Belarbi explained last year. “In addition, I support other projects such as the National Energy Water Treatment and Speciation (NEWTS) Database and geologic carbon storage.”

Belarbi was part of an NETL team that invented a new self-healing cold spray coating for internal pipeline corrosion protection that can help protect against corrosion in natural gas, hydrogen and CO2 pipelines. Pipeline corrosion can cause catastrophic failure events such as explosions and emissions of environmentally damaging substances like methane.

“My professor at college inspired me to pursue a career of engineering,” Belarbi said. “I am a very curious and experimental person, and I love that the combination of engineering and chemistry offers us the ability to design and create new materials that can improve and advance the economy.”

Belarbi received a Ph.D. in chemical engineering from Sorbonne University (ex. Pierre and Marie Curie University-Paris IV) France in 2013. She built a solid background in electrochemistry to further explore the inhibition of calcium carbonate deposition on metal surfaces.

Before joining NETL, Belarbi was a project leader at the Institute for Corrosion and Multiphase Technology at Ohio University where her research focused on using corrosion inhibitors to mitigate internal corrosion in oil and gas pipelines. Belarbi also worked at the Institute for Sustainable Energy and the Environment, Ohio University, where she investigated the electrochemical removal of nutrients from animal wastewater.

AMPP is a global community of professionals focused on the protection of assets and the performance of industrial and natural materials. AMPP is the world’s largest corrosion control and protective coatings organization, serving more than 35,000 members in over 140 countries. AMPP is headquartered in the United States with offices in Houston and Pittsburgh, and additional offices in Brazil, Canada, China, Dubai (training center), Malaysia, Saudi Arabia and the United Kingdom.

Source

January 2, 2024

NETL researchers invented a new self-healing cold spray coating for use inside pipelines. The coating protects against corrosion, which can cause catastrophic events such as explosions and methane emissions.

“The invention consists of a new zinc-rich material that creates an effective protective layer which resists dissolution compared to existing zinc sacrificial coatings,” NETL’s Ömer Doğan, who worked on the innovation with NETL researchers Joseph Tylczak, and Margaret Ziomek-Moroz, said. ‘This new material can be applied to steel structures in a cold spray process to protect them from the effects of corrosion.”

Cold spray is a high-energy solid-state coating and powder consolidation process for application of metals, metal alloys, and metal blends for numerous applications. It uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic nozzle for particle adhesion. The coating can be applied to the interior of a pipeline by using a robotic cold spray device.

Source: Dave Kovaleski, DailyEnergyInsider, 1/2/2024

NETL researchers invented a new self-healing cold spray coating for use inside pipelines. The coating protects against corrosion, which can cause catastrophic events such as explosions and methane emissions.

“The invention consists of a new zinc-rich material that creates an effective protective layer which resists dissolution compared to existing zinc sacrificial coatings,” NETL’s Ömer Doğan, who worked on the innovation with NETL researchers Joseph Tylczak, and Margaret Ziomek-Moroz, said. ‘This new material can be applied to steel structures in a cold spray process to protect them from the effects of corrosion.”

Cold spray is a high-energy solid-state coating and powder consolidation process for application of metals, metal alloys, and metal blends for numerous applications. It uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic nozzle for particle adhesion. The coating can be applied to the interior of a pipeline by using a robotic cold spray device.

Source: Dave Kovaleski, DailyEnergyInsider, 1/2/2024

December 28, 2023

A recent analysis published by Stanford University included 26 current and former NETL researchers in the top 2% of global scientists, underscoring the deep pool of talent at the U.S. Department of Energy national laboratory focused on creating a clean energy future.

“We have some of the most advanced scientific facilities in the world, but it is our people that make the difference,” NETL Acting Director Sean Plasynski said. “The Stanford analysis looks at the impact researchers have within their scientific communities, and it’s clear that our work reverberates well beyond the Lab.”

The analysis comprised lists according to career-long impact and single-year impact.

Current and former NETL researchers listed in the top 2% for career-long impact were Dominic Alfonso, David E. Alman, Sofiane Benyahia, Ray Boswell, Ronald W. Breault, Yuhua Duan, Michael C. Gao, Randall S. Gemmen, Angela L. Goodman, Evan J. Granite, Jeffrey Hawk, Gordon R. Holcomb, Mehrdad Massoudi, James Rawers, Wissam Saidi, Harpreet Singh, Ranjani Siriwardane, Dan C. Sorescu, D.H. Smith, Phuoc Tran and C.M. White.

Current and former NETL researchers listed in the top 2% for single-year impact were Sofiane Benyahia, Ray Boswell, Ronald W. Breault, Yuhua Duan, Michael C. Gao, Angela L. Goodman, Evan J. Granite, Jeffrey Hawk, Gordon R. Holcomb, Douglas Kauffman, Liqiang Lu, Ping Lu, Mehrdad Massoudi, Giannis Mpourmpakis, Wissam Saidi, Harpreet Singh, Ranjani Siriwardane, Yongkoo Seol, Dan C. Sorescu, and Phuoc Tran.

“It’s truly inspiring to see so many familiar names on these lists,” Plasynski said. “Even more impressive is that some of our researchers appear on both lists — showing an impressive research career backed by a phenomenal year of contributions to the research community.”

The analysis was conducted through the Departments of Medicine, of Health Research and Policy, of Biomedical Data Science, and of Statistics, and Meta-Research Innovation Center at Stanford University.

Source

Bold indicates an Albany Research Center researcher

A recent analysis published by Stanford University included 26 current and former NETL researchers in the top 2% of global scientists, underscoring the deep pool of talent at the U.S. Department of Energy national laboratory focused on creating a clean energy future.

“We have some of the most advanced scientific facilities in the world, but it is our people that make the difference,” NETL Acting Director Sean Plasynski said. “The Stanford analysis looks at the impact researchers have within their scientific communities, and it’s clear that our work reverberates well beyond the Lab.”

The analysis comprised lists according to career-long impact and single-year impact.

Current and former NETL researchers listed in the top 2% for career-long impact were Dominic Alfonso, David E. Alman, Sofiane Benyahia, Ray Boswell, Ronald W. Breault, Yuhua Duan, Michael C. Gao, Randall S. Gemmen, Angela L. Goodman, Evan J. Granite, Jeffrey Hawk, Gordon R. Holcomb, Mehrdad Massoudi, James Rawers, Wissam Saidi, Harpreet Singh, Ranjani Siriwardane, Dan C. Sorescu, D.H. Smith, Phuoc Tran and C.M. White.

Current and former NETL researchers listed in the top 2% for single-year impact were Sofiane Benyahia, Ray Boswell, Ronald W. Breault, Yuhua Duan, Michael C. Gao, Angela L. Goodman, Evan J. Granite, Jeffrey Hawk, Gordon R. Holcomb, Douglas Kauffman, Liqiang Lu, Ping Lu, Mehrdad Massoudi, Giannis Mpourmpakis, Wissam Saidi, Harpreet Singh, Ranjani Siriwardane, Yongkoo Seol, Dan C. Sorescu, and Phuoc Tran.

“It’s truly inspiring to see so many familiar names on these lists,” Plasynski said. “Even more impressive is that some of our researchers appear on both lists — showing an impressive research career backed by a phenomenal year of contributions to the research community.”

The analysis was conducted through the Departments of Medicine, of Health Research and Policy, of Biomedical Data Science, and of Statistics, and Meta-Research Innovation Center at Stanford University.

Source

Bold indicates an Albany Research Center researcher

November 13, 2023

As a recognized leader in research data curation, collaboration and virtualization for the national decarbonization effort, NETL’s geo-data infrastructure work was on display at national summits in October. The Lab’s digital infrastructure and resources are invaluable in advancing decarbonization projects related to carbon capture and storage (CCS), critical minerals (CM) and hydrogen.

At the 2023 National Academies of Science, Engineering, and Medicine's U.S. Research Data Summit and separately at the 2023 Geological Society of America (GSA) Connects Conference, NETL showcased its cutting-edge data infrastructure. Both of these summits were important opportunities for NETL to share and raise awareness for its focus on the development of advanced, safe and reliable data-science solutions to support the nation’s transition to a decarbonized economy and energy sector to address climate change.

One key NETL-developed asset showcased during these conferences was the Energy Data eXchange (EDX), a robust, mature and highly relevant data repository aligned with the summit's goals of enhancing collaboration and reducing research duplication. EDX offers vetted, authoritative resources, facilitating the development of safe, reliable next-generation technologies for various stakeholders, including commercial, regulatory and research and development professionals. Soon, EDX will transition to a multi-cloud environment, improving accessibility and integrating artificial intelligence (AI) and machine learning (ML) technologies to democratize digital infrastructure for all while specifically addressing CCS challenges.

The recently released Executive Order on “The Safe, Secure, and Trustworthy Development and Use of Artificial Intelligence” features directives on ensuring safe and secure implementation of AI and data-driven efforts. EDX and NETL’s Science-based AI/Ml Institute (SAMI) are working with DOE leadership to support and meet the requirements delineated under this executive order.

The EDX upgrade aligns with SAMI, which leverages AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production. Since 2020, SAMI has focused on ensuring the appropriate and trustworthy reuse of data, such as that stored on EDX, to drive applied energy research in line with decarbonization needs.

NETL decarbonization efforts several areas of research in CCS. NETL has launched EDX DisCO2ver, a Bipartisan Infrastructure Law-funded platform with data integration, model/tool virtualization, and the capacity to be a central hub for diverse Energy Data eXchange for Carbon Capture and Sequestration (EDX4CCS), like the CO2-Locate Database, the Class VI Data Support Tool Geodatabase, the CO2 Pipeline Route Planning Database and the CCS Environmental Justice-Social Justice (EJ-SJ) Database, as well as those from the National Energy Risk Assessment Partnership (NRAP).

NETL is also developing EDX Spatial, a spatial data visualization platform that allows researchers and industry professionals to map out historical data collection points, enhancing accessibility and user comprehension of the vast data resources.

Kelly Rose, Ph.D., NETL’s senior fellow for computational science and engineering, highlighted the democratization of data for energy research at the summit as a panelist speaker. EDX4CCS was also featured as a prime resource for addressing CCS needs on the summit’s pre-event support document.

NETL developments were also featured at the GSA Connects Conference, an event that promoted cross-sector collaboration in geoscience. NETL highlighted research in CCS, CM and hydrogen at the conference. EDX supports the safe, secure, and responsible data-driven future for CCS, critical minerals and hydrogen.

These products and developments are supporting NETL’s role in decarbonization and will enhance future efforts, such as the DOE-funded hydrogen hub projects, driving low-cost, clean hydrogen development. All these research sectors align closely with the White House's Energy Communities effort and other U.S. Department of Energy (DOE) programs dedicated to fostering equitable transitions for economic, environmental and social progress.

Source

As a recognized leader in research data curation, collaboration and virtualization for the national decarbonization effort, NETL’s geo-data infrastructure work was on display at national summits in October. The Lab’s digital infrastructure and resources are invaluable in advancing decarbonization projects related to carbon capture and storage (CCS), critical minerals (CM) and hydrogen.

At the 2023 National Academies of Science, Engineering, and Medicine's U.S. Research Data Summit and separately at the 2023 Geological Society of America (GSA) Connects Conference, NETL showcased its cutting-edge data infrastructure. Both of these summits were important opportunities for NETL to share and raise awareness for its focus on the development of advanced, safe and reliable data-science solutions to support the nation’s transition to a decarbonized economy and energy sector to address climate change.

One key NETL-developed asset showcased during these conferences was the Energy Data eXchange (EDX), a robust, mature and highly relevant data repository aligned with the summit's goals of enhancing collaboration and reducing research duplication. EDX offers vetted, authoritative resources, facilitating the development of safe, reliable next-generation technologies for various stakeholders, including commercial, regulatory and research and development professionals. Soon, EDX will transition to a multi-cloud environment, improving accessibility and integrating artificial intelligence (AI) and machine learning (ML) technologies to democratize digital infrastructure for all while specifically addressing CCS challenges.

The recently released Executive Order on “The Safe, Secure, and Trustworthy Development and Use of Artificial Intelligence” features directives on ensuring safe and secure implementation of AI and data-driven efforts. EDX and NETL’s Science-based AI/Ml Institute (SAMI) are working with DOE leadership to support and meet the requirements delineated under this executive order.

The EDX upgrade aligns with SAMI, which leverages AI/ML and high-performance computing to accelerate technology development for clean and efficient energy production. Since 2020, SAMI has focused on ensuring the appropriate and trustworthy reuse of data, such as that stored on EDX, to drive applied energy research in line with decarbonization needs.

NETL decarbonization efforts several areas of research in CCS. NETL has launched EDX DisCO2ver, a Bipartisan Infrastructure Law-funded platform with data integration, model/tool virtualization, and the capacity to be a central hub for diverse Energy Data eXchange for Carbon Capture and Sequestration (EDX4CCS), like the CO2-Locate Database, the Class VI Data Support Tool Geodatabase, the CO2 Pipeline Route Planning Database and the CCS Environmental Justice-Social Justice (EJ-SJ) Database, as well as those from the National Energy Risk Assessment Partnership (NRAP).

NETL is also developing EDX Spatial, a spatial data visualization platform that allows researchers and industry professionals to map out historical data collection points, enhancing accessibility and user comprehension of the vast data resources.

Kelly Rose, Ph.D., NETL’s senior fellow for computational science and engineering, highlighted the democratization of data for energy research at the summit as a panelist speaker. EDX4CCS was also featured as a prime resource for addressing CCS needs on the summit’s pre-event support document.

NETL developments were also featured at the GSA Connects Conference, an event that promoted cross-sector collaboration in geoscience. NETL highlighted research in CCS, CM and hydrogen at the conference. EDX supports the safe, secure, and responsible data-driven future for CCS, critical minerals and hydrogen.

These products and developments are supporting NETL’s role in decarbonization and will enhance future efforts, such as the DOE-funded hydrogen hub projects, driving low-cost, clean hydrogen development. All these research sectors align closely with the White House's Energy Communities effort and other U.S. Department of Energy (DOE) programs dedicated to fostering equitable transitions for economic, environmental and social progress.

Source

September 21, 2023

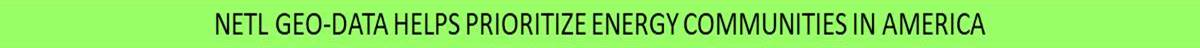

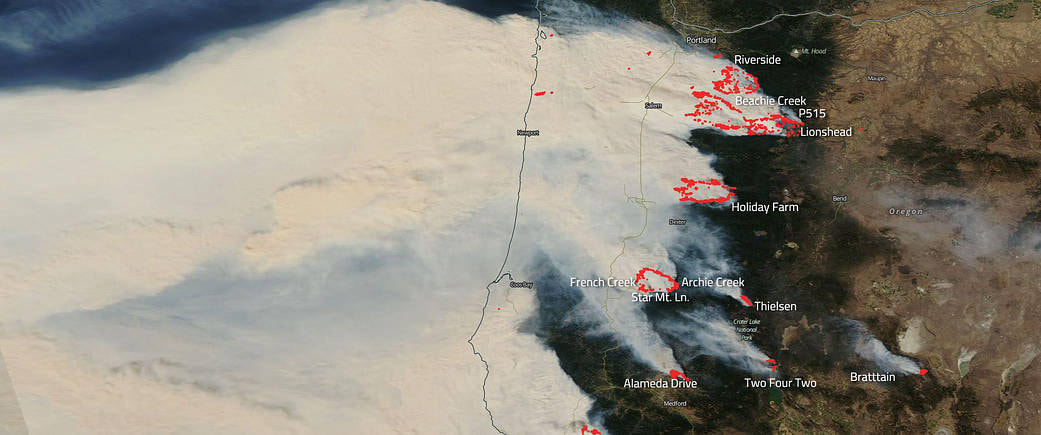

With insights from custom mapping and data science analyses, NETL is helping prioritize energy communities and spotlight opportunities for economic improvement and environmental justice in a changing energy landscape.

“The release and sharing of these data and maps provide critical information for U.S. communities; allowing them to evaluate funding opportunities, tax credits, as well as opportunities for clean energy transitions,” said NETL Geo-data Scientist Jennifer Bauer. “The data and analyses underpinning different definitions of energy communities wasn’t previously accessible, so making these data and maps publicly available is a major asset to a variety of stakeholders and decision makers throughout the nation.”

Since 2021, increasing demand for energy, environmental, community, and justice data lead to a growth in energy mapping and visualization projects with NETL’s geo-data science experts. NETL has performed rapid analytics on hundreds of energy, environmental, and community-level data sets to meet these demands, resulting in publicly accessible data and interactive maps that can help drive investments in energy communities, inform community and stakeholder engagement, support economic revitalization, strengthen American supply chains, and create jobs from the new clean energy economy.

Source

With insights from custom mapping and data science analyses, NETL is helping prioritize energy communities and spotlight opportunities for economic improvement and environmental justice in a changing energy landscape.

“The release and sharing of these data and maps provide critical information for U.S. communities; allowing them to evaluate funding opportunities, tax credits, as well as opportunities for clean energy transitions,” said NETL Geo-data Scientist Jennifer Bauer. “The data and analyses underpinning different definitions of energy communities wasn’t previously accessible, so making these data and maps publicly available is a major asset to a variety of stakeholders and decision makers throughout the nation.”

Since 2021, increasing demand for energy, environmental, community, and justice data lead to a growth in energy mapping and visualization projects with NETL’s geo-data science experts. NETL has performed rapid analytics on hundreds of energy, environmental, and community-level data sets to meet these demands, resulting in publicly accessible data and interactive maps that can help drive investments in energy communities, inform community and stakeholder engagement, support economic revitalization, strengthen American supply chains, and create jobs from the new clean energy economy.

Source

August 21, 2023

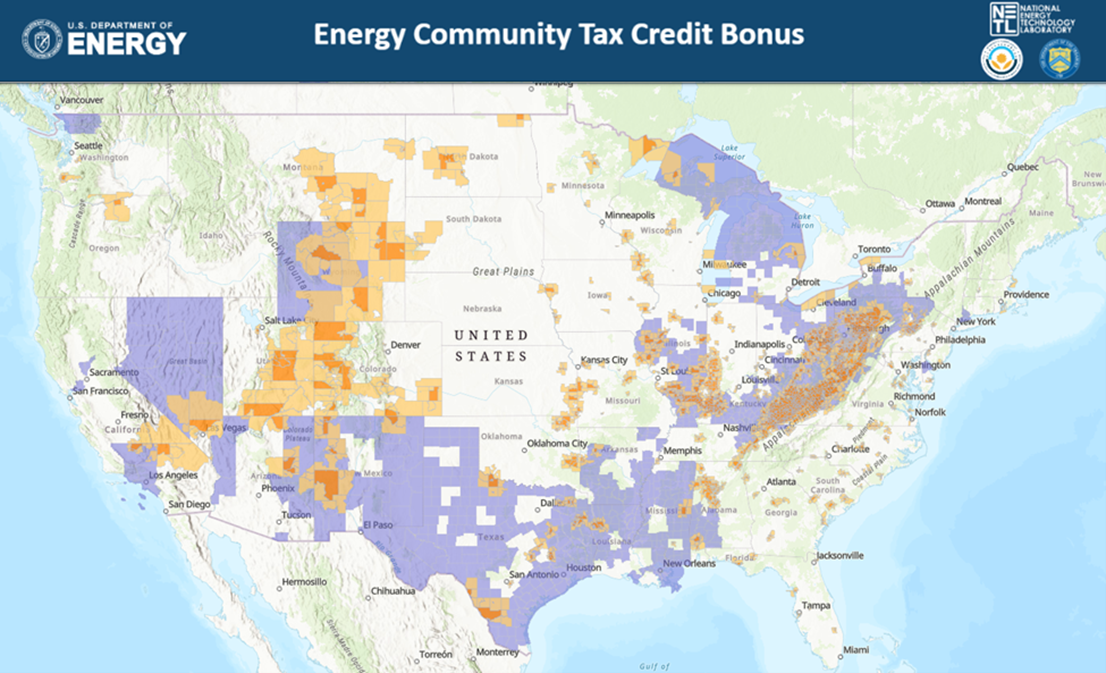

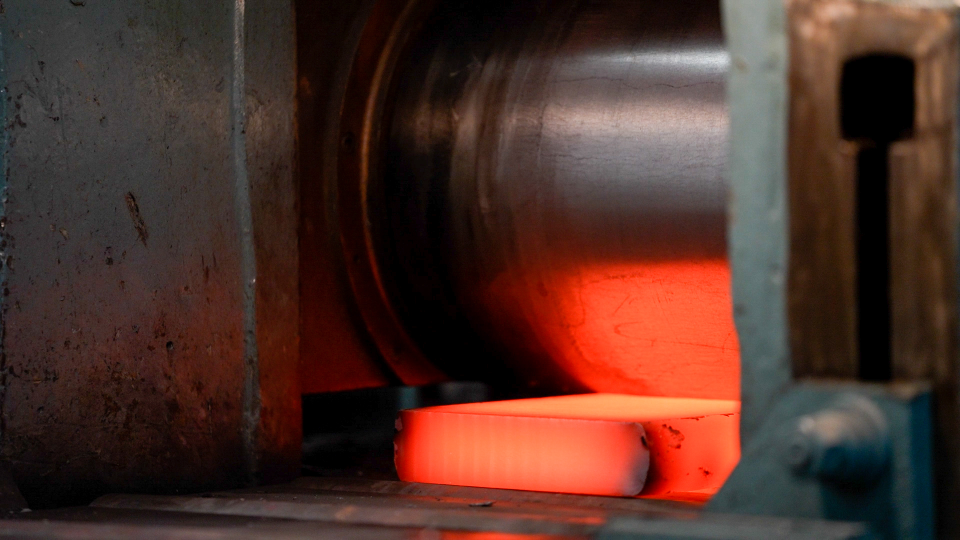

Researchers on NETL’s Structural Materials Team produced a more robust pipeline material for transporting hydrogen and captured carbon dioxide (CO2) by adding the rare earth element (REE) cerium to create a tougher steel alloy. The accomplishment simultaneously addresses two important U.S. Department of Energy priorities: development of infrastructure needed for decarbonization and improvement of the critical minerals supply chain.

Researchers explained that the added cerium reacts with oxygen and sulfur impurities that are introduced during the steel manufacturing and eliminates the negative impact of those impurities, producing a steel that is less susceptible to cracking during its service life. Testing at NETL has shown that cerium additions to X90 pipeline steel can improve the Charpy impact toughness—a measure of the steel’s ability to absorb energy and resist crack propagation—by up to 50%.

“Such an improvement is important for new pipelines, where running ductile fracture is a major concern, such as for carbon dioxide transport. These results show promise, and more research is needed to determine the impact of cerium on other important steel properties such as weldability.” said NETL Research Scientist Richard Oleksak. “Better steel isn’t the only potential benefit,” he added “Cerium, which is the most abundant rare earth element in both conventional and unconventional domestic feedstocks, is currently a major unused byproduct of the extraction of more valuable rare earths. This means we could see the creation of applications for cerium to meet industrial demand.” He said that with global steel production at two billion tons annually, the incorporation of even small amounts of cerium into this industry would significantly increase its demand. By developing high-volume applications for cerium, the value proposition for domestic production of rare earths is improved, thereby enhancing the supply chain for these critical minerals.

REEs have a long history in iron and steelmaking. Specifically, cerium, lanthanum, and cerium/lanthanum-rich alloys have been used in some form since the 1950s. The cost of cerium and lanthanum has decreased significantly since the major work involving these elements in iron and steelmaking in the mid-1900s.

A major driver of this cost reduction is related to the so-called rare earth balance problem. That is, both cerium and lanthanum co-occur with other REEs, such as neodymium, in both conventional and unconventional domestic feedstocks. Because of the high demand of neodymium and other REEs for various clean energy technologies, and the likely increase in demand for these technologies in the era of global decarbonization, it is very likely that tremendous amounts of unused cerium and lanthanum will be produced in the coming decades.

“This presents anexcellent opportunity for the renewed consideration of these rare earths as promising and inexpensive alloy additions in steelmaking,” Oleksak said. “The success of NETL in developing cerium-enhanced steel alloys is an example of the potential economic and environmental benefits to come from acting on such opportunities.”

Significant new pipeline infrastructure improvements are expected within the coming years that can help the nation facilitate decarbonization goals, including pipelines specifically designed for CO2 and hydrogen transport. Both uses pose unique challenges and place increased reliance on the integrity of the steel products.

Source

Researchers on NETL’s Structural Materials Team produced a more robust pipeline material for transporting hydrogen and captured carbon dioxide (CO2) by adding the rare earth element (REE) cerium to create a tougher steel alloy. The accomplishment simultaneously addresses two important U.S. Department of Energy priorities: development of infrastructure needed for decarbonization and improvement of the critical minerals supply chain.

Researchers explained that the added cerium reacts with oxygen and sulfur impurities that are introduced during the steel manufacturing and eliminates the negative impact of those impurities, producing a steel that is less susceptible to cracking during its service life. Testing at NETL has shown that cerium additions to X90 pipeline steel can improve the Charpy impact toughness—a measure of the steel’s ability to absorb energy and resist crack propagation—by up to 50%.

“Such an improvement is important for new pipelines, where running ductile fracture is a major concern, such as for carbon dioxide transport. These results show promise, and more research is needed to determine the impact of cerium on other important steel properties such as weldability.” said NETL Research Scientist Richard Oleksak. “Better steel isn’t the only potential benefit,” he added “Cerium, which is the most abundant rare earth element in both conventional and unconventional domestic feedstocks, is currently a major unused byproduct of the extraction of more valuable rare earths. This means we could see the creation of applications for cerium to meet industrial demand.” He said that with global steel production at two billion tons annually, the incorporation of even small amounts of cerium into this industry would significantly increase its demand. By developing high-volume applications for cerium, the value proposition for domestic production of rare earths is improved, thereby enhancing the supply chain for these critical minerals.

REEs have a long history in iron and steelmaking. Specifically, cerium, lanthanum, and cerium/lanthanum-rich alloys have been used in some form since the 1950s. The cost of cerium and lanthanum has decreased significantly since the major work involving these elements in iron and steelmaking in the mid-1900s.

A major driver of this cost reduction is related to the so-called rare earth balance problem. That is, both cerium and lanthanum co-occur with other REEs, such as neodymium, in both conventional and unconventional domestic feedstocks. Because of the high demand of neodymium and other REEs for various clean energy technologies, and the likely increase in demand for these technologies in the era of global decarbonization, it is very likely that tremendous amounts of unused cerium and lanthanum will be produced in the coming decades.

“This presents anexcellent opportunity for the renewed consideration of these rare earths as promising and inexpensive alloy additions in steelmaking,” Oleksak said. “The success of NETL in developing cerium-enhanced steel alloys is an example of the potential economic and environmental benefits to come from acting on such opportunities.”

Significant new pipeline infrastructure improvements are expected within the coming years that can help the nation facilitate decarbonization goals, including pipelines specifically designed for CO2 and hydrogen transport. Both uses pose unique challenges and place increased reliance on the integrity of the steel products.

Source

August 15, 2023

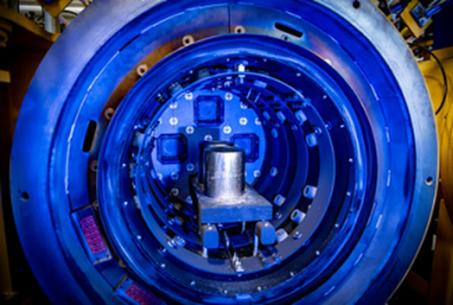

An invention reported by researchers from NETL can help protect against corrosion in natural gas, hydrogen, and carbon dioxide (CO2) pipelines. Pipeline corrosion can cause catastrophic failure events such as explosions and emissions of environmentally damaging substances like methane. The innovation is a new self-healing cold spray coating for internal pipeline corrosion protection.

According to NETL’s Ömer Doğan, who worked on the innovation with NETL researchers Joseph Tylczak, and Margaret Ziomek-Moroz, and Zineb Belarbi, internal pipeline corrosion is a common problem. “Internal corrosion in pipelines primarily is due to the presence of water, carbon dioxide, and hydrogen sulfide contained in natural gas,” Doğan explained. “Internal corrosion can eventually result in leakage, cracks, and rupture of the pipeline leading to explosion hazards and methane emissions.”

Traditional approaches to fighting pipeline corrosion included use of inhibitors or organic coatings such as fusion-bonded epoxy and polyurethane. Injection of inhibitors in natural gas or CO2 pipelines is challenging because of the difficulty of transporting the inhibitor along the pipelines. The main disadvantage of using organic coatings for internal pipeline protection is that they have poor abrasion resistance and can form a corrosion focal point.

Doğan said another approach is to use sacrificial coatings to protect pipelines and equipment from internal corrosion. A sacrificial coating, or anode, undergoes oxidation more than the metal surface it protects, effectively stopping oxidation on the metal. However, the existing sacrificial coatings tend to dissolve too fast in natural gas pipelines. “The invention consists of a new zinc-rich material that creates an effective protective layer which resists dissolution compared to existing zinc sacrificial coatings,” Doğan said. ‘This new material can be applied to steel structures in a cold spray process to protect them from the effects of corrosion.”

Cold spray is a high-energy solid-state coating and powder consolidation process for application of metals, metal alloys, and metal blends for numerous applications. Cold spray uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic nozzle for particle adhesion. The coating can be applied to the interior of a pipeline by using a robotic cold spray device attached to a pipeline pig.

Just some of the features and advantages of the new zinc-rich coating approach compared to existing approaches include its ability to:

A Report of Invention (ROI) was disclosed June 30, 2023, and assigned 23N-12.

Source

An invention reported by researchers from NETL can help protect against corrosion in natural gas, hydrogen, and carbon dioxide (CO2) pipelines. Pipeline corrosion can cause catastrophic failure events such as explosions and emissions of environmentally damaging substances like methane. The innovation is a new self-healing cold spray coating for internal pipeline corrosion protection.

According to NETL’s Ömer Doğan, who worked on the innovation with NETL researchers Joseph Tylczak, and Margaret Ziomek-Moroz, and Zineb Belarbi, internal pipeline corrosion is a common problem. “Internal corrosion in pipelines primarily is due to the presence of water, carbon dioxide, and hydrogen sulfide contained in natural gas,” Doğan explained. “Internal corrosion can eventually result in leakage, cracks, and rupture of the pipeline leading to explosion hazards and methane emissions.”

Traditional approaches to fighting pipeline corrosion included use of inhibitors or organic coatings such as fusion-bonded epoxy and polyurethane. Injection of inhibitors in natural gas or CO2 pipelines is challenging because of the difficulty of transporting the inhibitor along the pipelines. The main disadvantage of using organic coatings for internal pipeline protection is that they have poor abrasion resistance and can form a corrosion focal point.

Doğan said another approach is to use sacrificial coatings to protect pipelines and equipment from internal corrosion. A sacrificial coating, or anode, undergoes oxidation more than the metal surface it protects, effectively stopping oxidation on the metal. However, the existing sacrificial coatings tend to dissolve too fast in natural gas pipelines. “The invention consists of a new zinc-rich material that creates an effective protective layer which resists dissolution compared to existing zinc sacrificial coatings,” Doğan said. ‘This new material can be applied to steel structures in a cold spray process to protect them from the effects of corrosion.”

Cold spray is a high-energy solid-state coating and powder consolidation process for application of metals, metal alloys, and metal blends for numerous applications. Cold spray uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic nozzle for particle adhesion. The coating can be applied to the interior of a pipeline by using a robotic cold spray device attached to a pipeline pig.

Just some of the features and advantages of the new zinc-rich coating approach compared to existing approaches include its ability to:

- Remain stable regardless of temperature/pressure changes of the service environment.

- Not form defects during cold spray deposition resulting in its extended life.

- Self-heal when damaged by forming protective corrosion products.

- Not require a periodic application (long life).

- Be used as structural material to repair used/damaged pipeline.

A Report of Invention (ROI) was disclosed June 30, 2023, and assigned 23N-12.